Welcome to Tangshan Moneide Trading Co., Ltd.

application of phase transfer catalyst

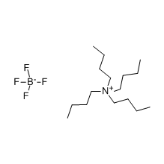

Introduction to Chiral Phase Transfer Catalysis In the dynamic field of synthetic organic chemistry, the demand for highly selective and efficient methodologies is paramount. Chiral phase transfer catalyst (CPTC) systems represent a cornerstone technology, enabling the synthesis of enantiomerically enriched compounds under mild and environmentally benign conditions. These catalysts facilitate reactions between substrates located in immiscible phases, often aqueous and organic, by transporting one reactant into the other phase. The "chiral" aspect introduces stereoselectivity, which is critical for pharmaceuticals, agrochemicals, and fine chemical production where specific enantiomers can have vastly different biological activities. The development of CPTCs has revolutionized asymmetric synthesis, offering a powerful alternative to traditional methods that often require expensive chiral auxiliaries, stoichiometric reagents, or cryogenic temperatures. Our focus is on advanced phosphonium salt-based CPTCs, exemplified by compounds like Butyl Triphenyl Phosphonium Bromide, which serve as versatile platforms for a wide range of transformations, including asymmetric alkylations, additions, and cyclizations. These catalysts embody the principles of phase transfer catalyst in green chemistry , minimizing solvent usage and promoting atom economy. Manufacturing Process of Chiral Phase Transfer Catalysts The synthesis of high-purity chiral phase transfer catalyst involves a meticulously controlled multi-step process, ensuring the desired enantioselectivity and catalytic efficiency. This section outlines a general manufacturing flow, drawing on common methodologies for phosphonium-based CPTCs. Process Flow Schematic: Raw Material Sourcing & Qualification: High-purity precursors such as phosphines (e.g., triphenylphosphine), alkyl halides (e.g., n-butyl bromide), and chiral auxiliaries (e.g., cinchona alkaloids or their derivatives) are rigorously tested for purity (typically >99%) via GC-MS and NMR spectroscopy. Our materials adhere to ISO 9001 quality standards. Quaternization Reaction (Stage 1 - Phosphonium Salt Formation): The phosphine is reacted with an alkyl halide in a suitable solvent (e.g., toluene, acetonitrile) under controlled temperature and inert atmosphere (nitrogen) to form the primary phosphonium salt. This step, often a facile SN2 reaction, typically takes 4-8 hours at reflux. R 3 P + R'X → [R 3 PR'] + X - (e.g., P(C 6 H 5 ) 3 + CH 3 (CH 2 ) 3 Br → [(C 6 H 5 ) 3 P(CH 2 ) 3 CH 3 ] + Br - ) Chiral Auxiliary Attachment (Stage 2 - Asymmetric Modification): The achiral phosphonium salt undergoes further reaction with a carefully selected chiral auxiliary. This might involve an anion exchange to introduce a chiral counterion, or a direct covalent attachment of a chiral moiety to the phosphonium center or an appended linker. Reaction conditions (temperature, pH, solvent) are optimized for enantioselectivity, often involving mild base catalysis and precise temperature control for 12-24 hours. This stage is critical for imparting the desired chirality. Purification & Isolation: The crude product is subjected to multi-stage purification, including solvent extraction, recrystallization, and chromatographic separation (e.g., silica gel chromatography for small batches or large-scale precipitation for bulk). This removes unreacted starting materials, byproducts, and any racemic impurities. Drying & Quality Control: The purified CPTC is dried under vacuum (e.g., 60°C, <1 mmHg) to achieve a moisture content of <0.5%. Rigorous testing follows: NMR Spectroscopy ( 1 H, 13 C, 31 P) for structural confirmation. High-Performance Liquid Chromatography (HPLC) for chemical purity (>99.5%). Chiral HPLC or GC for enantiomeric excess (ee), targeting >95% ee. Melting Point determination and elemental analysis. Specific rotation measurement. Packaging & Storage: The final product is packaged in inert atmosphere (argon/nitrogen) under controlled humidity conditions to prevent degradation, typically in amber glass bottles or drums. Our manufacturing processes are compliant with ISO 14001 environmental management standards, emphasizing solvent recycling and waste minimization. The target industries for these advanced catalysts include pharmaceuticals, agrochemicals, and specialized fine chemical synthesis. CPTCs offer advantages such as energy saving through room temperature reactions and enhanced corrosion resistance by avoiding strong acids/bases in some applications. The typical service life of our catalysts, when stored correctly, exceeds 3 years. Industry Trends and Market Insights for Chiral Catalysis The global market for chiral catalysts is experiencing robust growth, driven by increasing demand for enantiomerically pure intermediates in the pharmaceutical and agricultural sectors. Projections indicate the market will reach approximately USD 6.5 billion by 2028, with a compound annual growth rate (CAGR) of over 8%. Key trends include: Green Chemistry Imperatives: A strong emphasis on sustainable processes is fueling the adoption of CPTCs, which often reduce solvent usage, minimize waste, and operate under milder conditions. This aligns perfectly with the principles of phase transfer catalyst in green chemistry . Biopharmaceutical Expansion: The surging pipeline of chiral drugs and biologics necessitates efficient and scalable asymmetric synthesis methods, directly boosting demand for high-performance chiral phase transfer catalyst . Advanced Material Science: Beyond traditional sectors, CPTCs are finding new applications in advanced materials, such as chiral polymers and liquid crystals, offering novel functionalities. Crown Ethers and Macrocycles: Research into novel chiral macrocycles, particularly phase transfer catalyst crown ether derivatives, is expanding the scope of PTC, offering enhanced selectivity and stability for challenging reactions. Flow Chemistry Integration: The integration of CPTC systems into continuous flow reactors is an emerging trend, promising improved process control, safety, and scalability for industrial production. These trends underscore the critical role of innovation in CPTC design and application to meet the evolving demands of various high-value industries. Technical Specifications: Butyl Triphenyl Phosphonium Bromide Butyl Triphenyl Phosphonium Bromide, a prominent example of a phosphonium-based phase transfer catalyst, is highly valued for its versatility in various organic syntheses. While primarily an achiral PTC, it forms the foundational structure upon which many advanced chiral phase transfer catalyst systems are built, either through direct chiral modification or as a component in a chiral catalytic cycle. Product Specification Table: Butyl Triphenyl Phosphonium Bromide Parameter Specification Method CAS No. 1779-51-7 Standard Reference Molecular Formula C 22 H 24 BrP Elemental Analysis Molecular Weight 411.30 g/mol Calculated Appearance White to off-white crystalline powder Visual Inspection Purity (HPLC) ≥ 99.0% USP/EP Compliant HPLC Water Content (Karl Fischer) ≤ 0.5% ASTM D1364 Melting Point 230-234 °C DSC Solubility Soluble in DCM, CHCl 3 , DMF, DMSO. Sparingly soluble in water. Empirical Testing This product, while achiral itself, serves as a versatile building block and common reagent in many organic syntheses, including Wittig reactions and as a precursor for the synthesis of more complex, specifically designed chiral phase transfer catalyst systems. Its high purity and consistent quality ensure reliable performance in industrial applications. Application Scenarios and Technical Advantages Chiral phase transfer catalyst systems offer unparalleled advantages in a multitude of synthetic applications, particularly where stereochemical control is paramount. Key Application Areas: Pharmaceutical Synthesis: Enantioselective synthesis of active pharmaceutical ingredients (APIs), including anti-cancer drugs, antibiotics, and cardiovascular agents. For instance, the asymmetric alkylation of glycine imines using cinchona alkaloid-derived CPTCs yields non-proteinogenic α-amino acids, crucial building blocks for peptidomimetics. Agrochemical Development: Production of chiral herbicides and insecticides, where the desired biological activity is often enantiomer-specific, reducing environmental impact and improving efficacy. Fine Chemicals and Flavors/Fragrances: Synthesis of chiral intermediates for specialty chemicals, as well as specific enantiomers for enhanced sensory properties in flavors and fragrances. Polymer Science: Creation of chiral polymers with unique optical and mechanical properties for advanced materials applications. Technical Advantages: High Enantioselectivity: Achieving enantiomeric excesses (ee) often exceeding 95%, critical for regulatory compliance in pharmaceutical industries. Mild Reaction Conditions: Reactions frequently proceed at room temperature and atmospheric pressure, reducing energy consumption and minimizing degradation of sensitive substrates. Cost-Effectiveness: Relatively low catalyst loadings (0.1-10 mol%) and the ability to use inexpensive, readily available starting materials lead to significant cost savings compared to stoichiometric chiral auxiliaries. Green Chemistry Profile: Reduced need for hazardous organic solvents, often enabling biphasic reactions with water, aligning with phase transfer catalyst in green chemistry principles. Simplified work-up procedures also contribute to waste reduction. Scalability: CPTC reactions are often amenable to large-scale industrial production, facilitating efficient process development from lab to plant. Broad Substrate Scope: Versatility across a wide range of substrates and reaction types, including alkylations, Michael additions, epoxidations, and cyclopropanations. These advantages position CPTCs as a superior choice for advanced synthetic challenges requiring precise control over molecular architecture. Vendor Comparison: Key Differentiators in Chiral PTC Supply Choosing the right supplier for chiral phase transfer catalyst is critical for ensuring consistent product quality, reliable supply, and expert support. While many suppliers exist, differentiation often comes down to specific capabilities and commitments. Comparison Metrics for Chiral PTC Providers: Feature MoneideChem (Our Offering) Typical Competitor A Typical Competitor B Product Purity (ee) ≥98% ee (customizable to >99.5%) ≥95% ee ≥90% ee Manufacturing Certifications ISO 9001:2015, ISO 14001:2015 ISO 9001:2008 Basic QC Custom Synthesis Capability Extensive, fully supported R&D team Limited, for bulk orders only None Technical Support Dedicated chemists, application specialists Email support only Basic product data sheets Lead Time for Standard Products 3-7 business days (ex-stock) 7-14 business days Variable, 2-4 weeks Packaging Options Customizable from grams to metric tons Standard sizes (kg drums) Small lab packs only Customer Feedback (e.g., Reliability) Excellent, long-term partnerships Good for standard items Inconsistent for complex orders Our commitment to quality, robust R&D capabilities, and comprehensive customer support positions us as a leading partner for your chiral synthesis needs. We have partnered with over 50 clients globally in the last 15 years, consistently delivering high-quality phosphonium salts and derivatives. Customized Solutions and Application Case Studies Recognizing that every project has unique requirements, we offer extensive customization services for chiral phase transfer catalyst systems. Our expert chemists work directly with clients to design, synthesize, and optimize CPTCs for specific reactions and desired enantiomeric outcomes. Customization Capabilities: Ligand Modification: Tailoring the chiral moiety (e.g., cinchona alkaloid derivatives, phase transfer catalyst crown ether analogs) to achieve optimal stereocontrol for specific substrates. Counterion Tuning: Selecting appropriate counterions to influence solubility, activity, and separation characteristics. Backbone Variation: Modifying the phosphonium or ammonium backbone structure to enhance stability, recyclability, or reactivity. Process Optimization: Developing new synthetic routes for existing catalysts to improve yield, reduce costs, or enhance green chemistry metrics. Scale-Up Support: From gram-scale R&D to multi-ton commercial production, ensuring seamless transition and consistent quality. Application Case Study: Asymmetric Synthesis of a Pharmaceutical Intermediate Client: Leading Global Pharmaceutical Company (Tier 1) Challenge: The client required a highly enantioselective and scalable method for the asymmetric α-alkylation of a ketone, a crucial step in the synthesis of a novel anti-inflammatory drug candidate. Existing methods involved stoichiometric chiral auxiliaries, leading to high cost and significant waste. Solution: Our team collaborated closely with the client's R&D department. Based on initial screening, we proposed a novel cinchona alkaloid-derived phosphonium salt as a CPTC. Through iterative design and optimization, we customized the catalyst's structure, focusing on steric and electronic properties of the chiral moiety. Results: Achieved enantiomeric excess (ee) of 97.5% for the desired isomer, surpassing the client's target of 95% ee. Catalyst loading was optimized to 1 mol%, significantly reducing material costs. Reaction was successfully scaled up from gram to multi-kilogram scale using a water/toluene biphasic system, reducing overall solvent usage by 40%. The new process reduced overall manufacturing costs for this intermediate by approximately 25% and lowered waste generation by 30%. Client Feedback: "MoneideChem's expertise in chiral catalysis and their dedicated support were instrumental in overcoming a critical bottleneck in our drug synthesis. The customized PTC solution not only met our stringent purity requirements but also significantly improved the process's economic and environmental profile." - Head of Process Chemistry, Pharma Inc. Frequently Asked Questions (FAQ) Q: What is the primary difference between a chiral and an achiral phase transfer catalyst? A: An achiral phase transfer catalyst facilitates reactions between immiscible phases without influencing the stereochemistry of the product. A chiral phase transfer catalyst , however, incorporates a chiral moiety that induces asymmetry in the reaction, leading to the preferential formation of one enantiomer over the other, achieving enantioselective synthesis. Q: How do I select the right CPTC for my specific reaction? A: Selection depends on the type of reaction, the substrate's functional groups, and the desired enantioselectivity. Our technical support team provides expert consultation, starting with a review of your reaction conditions and desired outcome. We can suggest standard catalysts or develop a customized solution tailored to your needs. Q: What are your typical lead times and fulfillment processes? A: For in-stock standard products, lead time is typically 3-7 business days from order confirmation to shipment. For custom synthesis or large-volume orders, lead times are quoted individually based on complexity and quantity, generally ranging from 4-12 weeks. We utilize robust supply chain management to ensure timely and reliable delivery. Q: What warranty and after-sales support do you offer? A: All our products are guaranteed to meet the specified purity and quality standards as per their Certificate of Analysis for a period of 12 months from the date of shipment, provided they are stored under recommended conditions. We offer comprehensive after-sales support, including troubleshooting assistance, reaction optimization guidance, and detailed analytical support from our team of experienced chemists. Q: Can your CPTCs be recycled or reused? A: The recyclability of CPTCs depends on their specific design and the reaction conditions. Many of our solid-supported or highly stable CPTCs can be recovered and reused, contributing to their green chemistry profile and economic efficiency. We provide guidance on catalyst recovery methods where applicable, and our R&D team can design catalysts with enhanced recyclability. Authoritative References Maruoka, K. Recent developments in asymmetric phase-transfer catalysis. Pure Appl. Chem. 2008, 80 (5), 1055–1061. O'Donnell, M. J. The asymmetric phase-transfer-catalyzed alkylation of protected glycine imines. Acc. Chem. Res. 2004, 37 (8), 506–517. Deng, L. Asymmetric Catalysis with Chiral Quaternary Ammonium Salts. Acc. Chem. Res. 2004, 37 (11), 856–866. Shi, Y. Asymmetric Epoxidation of Olefins with Chiral Ketone Catalysts. Acc. Chem. Res. 2004, 37 (11), 843–855. Chinchilla, R.; Nájera, C. The Mizoroki-Heck Reaction in Phase-Transfer Catalysis. Chem. Rev. 2007, 107 (3), 874–922.

look at newproducts